Description

Volume pricing available for orders of 25, 50, 100, or 200 units

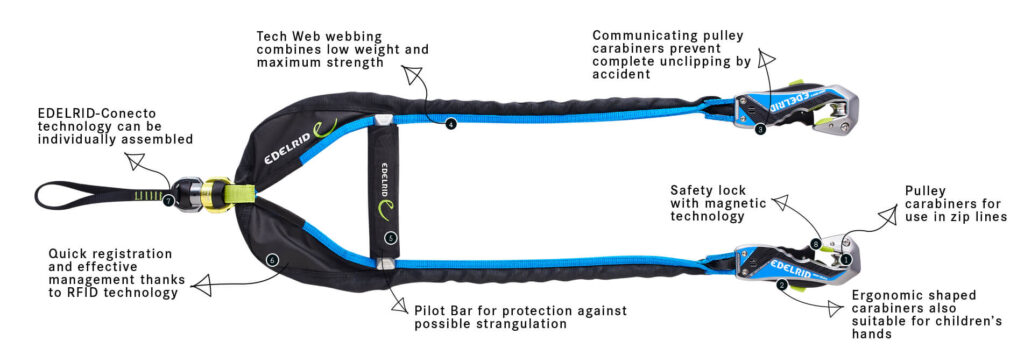

For adventure park operators, the bottleneck often lies in safety briefings and zip line transfers. The Edelrid Smart Belay X solves this by integrating communicating carabiner technology with a new Magnetic Safety Lock. Unlike traditional systems, the Smart Belay X only releases the gate when it detects the steel cable, preventing accidental unclipping. With built-in steel rollers, this smart belay system allows riders to transition seamlessly from climbing elements to zip lines without changing gear, significantly reducing queuing times and increasing operational ROI.

Ideal Applications

High-Throughput Adventure Parks: Reduces rider friction and gear handling.

Zipline-Heavy Courses: Integrated pulleys remove the need for separate trolleys.

Educational & Team Building: “Pilot Bar” offers intuitive handling and strangulation protection for inexperienced climbers.

Retrofit Projects: Compatible with existing 10 mm – 13 mm (0.39 – 0.51 in) cable lines without infrastructure changes.

Technical Specifications

Certifications: EN 17109 (Class D), EN 15567 (compatible).

Cable Compatibility: 10 mm – 13 mm (0.39 – 0.51 in) steel cable.

Weight: 1400 g (3.09 lbs).

Lanyard Length: 85 cm (33.5 in).

Safety Mechanism: Communicating carabiners with Magnetic Safety Lock (opens only on cable contact).

Tracking: Integrated RFID transponder for efficient PPE management.

Pulley System: Integrated steel rollers in carabiner spine.

| Intuitive use, even for children | Pilot Bar helps prevent strangulation |

| Enables overtaking and flexible visitor movement on course elements | Pilot Bar can be held on to difficult course sections |

| Quick and easy evacuation thanks to the opener | Pilot Bar helps control direction on zip lines (hands don’t touch the steel cable) |

| No need to switch to a double pulley for zip lines thanks to the Smart Belay pulley carabiner | Universally usable for all course elements and with all devices |

Operational Efficiency & Engineering

The Smart Belay X is designed to drive ROI through speed and safety. The communicating carabiner system mechanically prevents both clips from being open simultaneously. This redundancy is enhanced by the magnetic lock, which adds a layer of sensor-based verification, ensuring the gate can only open when actively pressed against the life safety line.

Increased Throughput: The integrated pulleys allow riders to roll freely on zip lines. This eliminates the “double pulley transfer” step, saving 30-60 seconds per zip line and reducing instructor intervention.

RFID Management: Built-in UHF RFID chips allow for rapid scanning of gear status and usage cycles, streamlining the daily inspection process.

Maintenance & Lifecycle

Built for the rigors of commercial use, the Smart Belay X features a modular design. Unlike riveted systems that require total replacement upon wear, key components like the pilot bar, lanyard, and shock absorber are field-replaceable.

Durability: Steel rollers reduce wear on the carabiner body during zip lining.

Serviceability: Modular construction allows for cost-effective repairs and extended product lifespan.

Inspection: Staff can perform functional checks independently; full annual inspections can be conducted by trained service partners.

Expert FAQ

Q: What cable diameter is the Smart Belay X compatible with? A: It is certified for use on steel cables between 10 mm and 13 mm (0.39 – 0.51 in).

Q: Does this system require a separate trolley for zip lines? A: No. The carabiners feature integrated steel pulleys, allowing them to function as a trolley on zip lines, significantly speeding up course flow.

Q: How does the magnetic locking feature work? A: The gate mechanism contains a sensor that detects the magnetic signature of the steel cable. The gate will physically not unlock unless it is in direct contact with the cable, preventing “air clipping.”

Q: Is the Smart Belay X compatible with EN 17109? A: Yes, it is fully certified to EN 17109 Class D, the standard for continuous safety systems (when used correctly) and communicating belay systems.