Description

The QuickFlight Free Fall Device solves the primary challenge of vertical descent elements: balancing high adrenaline with low maintenance costs. Unlike friction-based systems that require frequent pad replacements and cooling periods, Head Rush’s patented magnetic braking technology allows for high-throughput, continuous operation without thermal degradation. As a redundant, dual-line system certified to global safety standards (ASTM & CE), the QuickFlight offers operators a “set-and-forget” reliability that maximizes ROI while delivering a premium “stomach-flipping” drop.

Ideal Applications

High-Traffic Adventure Parks: Rapid retraction times enable high rider throughput (approx. 1 rider every 40 seconds).

Ropes Course Exits: Serves as a high-value finale element for linear courses.

Family Entertainment Centers (FECs): Compact footprint allows installation on indoor columns or existing towers.

Zip Line Towers: Utilizing vertical space for an additional revenue stream on existing platforms.

Technical Specifications

Safety Certifications:

ASTM F2291-11: Standard Practice for Design of Amusement Rides and Devices.

CE Marked: Certified to EN 341:2011-1A (Personal fall protection equipment – Descender devices for rescue) standards, fulfilling the rigorous testing for descent energy and dynamic strength.

Load Ratings:

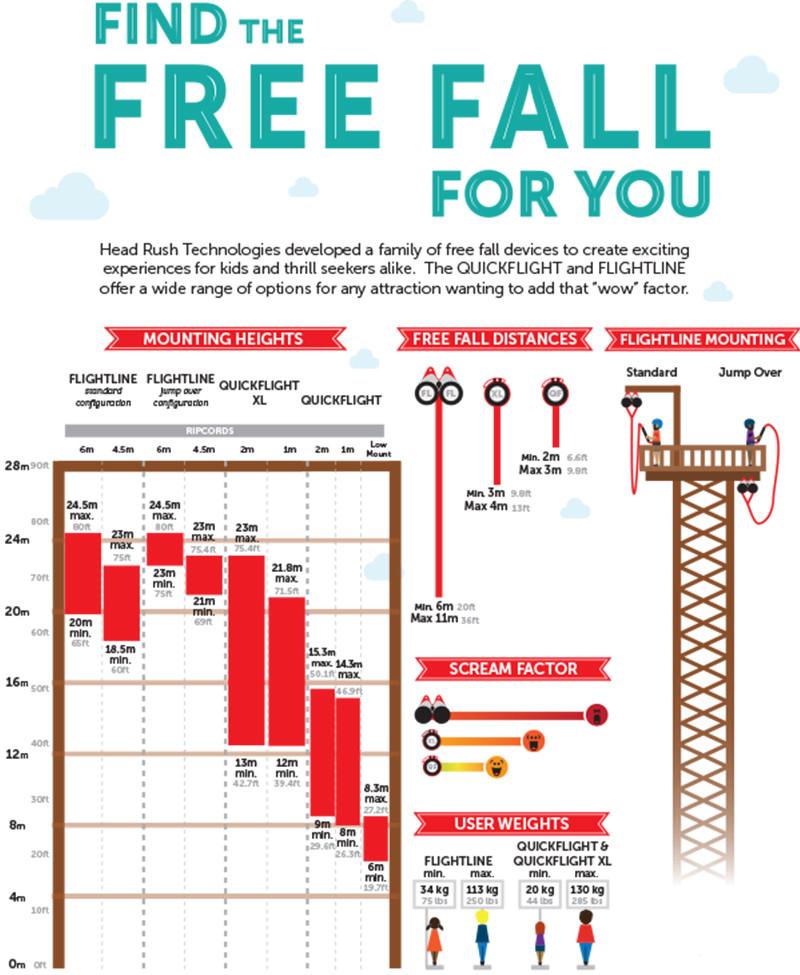

Rated Working Capacity (WLL): 20 – 130 kg (44 – 285 lbs).

Automatic Regulation: Self-adjusts resistance based on rider weight for consistent deceleration.

Mounting & Dimensions:

Device Dimensions: 80 x 320 x 216 mm (15 x 12.6 x 8.5 in).

Device Weight: 25 kg (55 lbs).

Mounting Height (Low Mount): 6.0 m – 8.3 m (19.7 ft – 27.2 ft).

Mounting Height (2m RipCord): 9.0 m – 15.3 m (29.6 ft – 50.1 ft).

Materials: Aluminum alloy housing; modified Acetal nozzle; UV-resistant nylon/Spectra webbing.

QuickFlight Annual Service

To maintain your QuickFlight Free Fall Devices warranty and ensure compliance with safety standards, all devices must undergo an annual service. Service is an annual process to make sure that your QuickFlight is operating properly and any worn parts, like the webbing, are replaced. Servicing your QuickFlight on time helps to maintain the warranty and maximize performance. Annual service is also mandatory to ensure compliance with safety standards like CE and ANSI.

Operational Efficiency & Engineering

The QuickFlight distinguishes itself through Eddy Current Magnetic Braking. This non-contact technology utilizes the electromagnetic force generated by the descent to create resistance.

Throughput: The retraction spring is tuned for rapid reset, allowing for a theoretical throughput of up to 90 participants per hour, minimizing queues.

Redundancy: Features a dual-line webbing system. If the primary line were to be compromised, the redundant line ensures a safe descent, satisfying strict risk assessment criteria (EN 15567 compliant operations).

Consistency: The braking force is proportional to the rider’s weight and speed. A 20 kg child and a 130 kg adult experience the same G-force profile during the catch, eliminating the need for operator adjustment.

Maintenance & Lifecycle

Designed for a low “Total Cost of Ownership,” the QuickFlight minimizes downtime.

Friction-Free: No contacting brake pads means no friction heat and no parts to wear out during the braking phase.

Service Intervals:

Annual Recertification: Required 15 months after manufacture, then every 12 months thereafter by an authorized service center.

Field Replaceable Parts: Upper webbing, RipCords, and nozzles can be inspected and replaced on-site by trained staff, reducing the need to ship the unit away for minor maintenance.

Durability: Sealed unit design protects internal components from weather and dust (though covers are recommended for extreme outdoor exposure).

Expert FAQ

Q: How does the “true free fall” mechanism work compared to an auto belay?

A: Unlike an auto belay that retracts slack immediately, the QuickFlight uses a “RipCord” system. The rider falls freely for a set distance (configured by RipCord length) before the webbing engages the magnetic braking drum, providing a distinct “drop” sensation before the catch.

Q: Is the device field-serviceable?

A: Yes. While the internal braking mechanism is sealed and requires annual factory recertification, the high-wear external components (webbing, carabiners, nozzle) are designed for field replacement by competent persons, ensuring maximum uptime during peak season.

Q: Can this device be used as a primary climber protection system (climbing up)?

A: No. The QuickFlight is a descent-only device. It must not be used as a belay for upward climbing. Riders should be clipped in at the platform edge immediately prior to descent.

Q: What is the minimum participant weight?

A: The system is rated for riders as light as 20 kg (44 lbs). The magnetic braking physics naturally produce less resistance for lighter riders, ensuring they descend smoothly without “hanging” or stopping mid-air.