Description

Stopping riders safely at speeds exceeding 60 kph presents a significant engineering challenge. Traditional friction brakes fade with heat, and spring packs create jarring g-forces that degrade the guest experience. The Head Rush zipSTOP SPEED Zip Line Brake solves this by utilizing advanced magnetic induction to automatically adjust resistance based on rider weight. As the flagship model in the zipSTOP line, it provides the robust braking power necessary for long-distance, gravity-fed commercial lines, ensuring consistent deceleration and industry-leading reliability.

Ideal Applications

Mega Zip Lines: Specifically engineered for lines with arrival speeds between 60–72 kph (37–45 mph).

High-Throughput Destinations: Automatic reset allows for rapid rider cycling, essential for high-volume tourist attractions.

Variable Rider Groups: Self-regulating braking curve accommodates weights from 15 kg to 150 kg (33–330 lbs) without manual adjustment.

All-Weather Operations: Magnetic braking performance is unaffected by rain, snow, or dust.

Technical Specifications

Braking Technology: Self-regulating Eddy Current (Magnetic Induction) with Internal Reduction.

Rated Working Velocity: 0 to 72 kph (0 to 45 mph).

Required Configuration: Must be used with an external 2:1 reduction line assembly.

Rated Working Capacity: 15 to 150 kg (33 to 330 lbs).

Device Weight: 23.5 kg (52 lbs).

Model Number: ZSSD150-20A.

Line Specifications: Maximum Line Extension of 20 m (65.6 ft).

Housing Materials: Aluminum Alloy / Zinc Plated Steel (Weather Resistant).

Certifications & Standards:

Third-party tested by an ISO 17025 accredited laboratory.

Compliant with ASTM F24 Standards for Amusement Rides and Devices.

Facilitates compliance with EN 15567 (Sports and Recreational Facilities).

Operational Efficiency & Engineering

The zipSTOP SPEED distinguishes itself through its dual-reduction architecture. By combining an internal gear reduction with a mandatory external 2:1 reduction line, the device effectively doubles the braking force applied to the rider while maintaining a smooth payout of the webbing.

Consistent Deceleration: The magnetic braking force increases proportionally to the rider’s velocity. Heavier or faster riders generate more resistance, resulting in the same comfortable stopping distance as lighter riders.

Zero-Friction Reliability: Unlike contact brakes, there are no brake pads to burn out or glaze. The braking mechanism is non-contact, meaning the core braking components have an indefinite fatigue life.

Automatic Reset: The unit automatically retracts the brake trolley for the next rider, significantly reducing guide workload and minimizing cycle times.

Maintenance & Lifecycle

Designed for low Cost of Ownership (COO) in commercial environments, the zipSTOP SPEED minimizes downtime through modular maintenance.

Service Intervals: Annual recertification is required (15 months from manufacture, then every 12 months) to maintain warranty and safety standards.

Consumables: The webbing brake line is a sacrificial wear part designed for field-replacement. Wear is visual and easily inspected during daily checks.

Durability: The unit is sealed against the elements, allowing for outdoor installation. However, for maximum longevity in harsh marine or sandy environments, a secondary protective cover is recommended.

Zipstop SPEED Annual Service

To maintain your zipSTOP SPEED Zip Line Brake warranty and ensure compliance with safety standards, all devices must undergo an annual service. Service is an annual process to make sure that your zipSTOP SPEED is operating properly and any worn parts, like the webbing, are replaced. Servicing your zipSTOP SPEED on time helps to maintain the warranty and maximize performance. Annual service is also mandatory to ensure compliance with safety standards like CE and ANSI. Check the zipSTOP SPEED Annual Service fee.

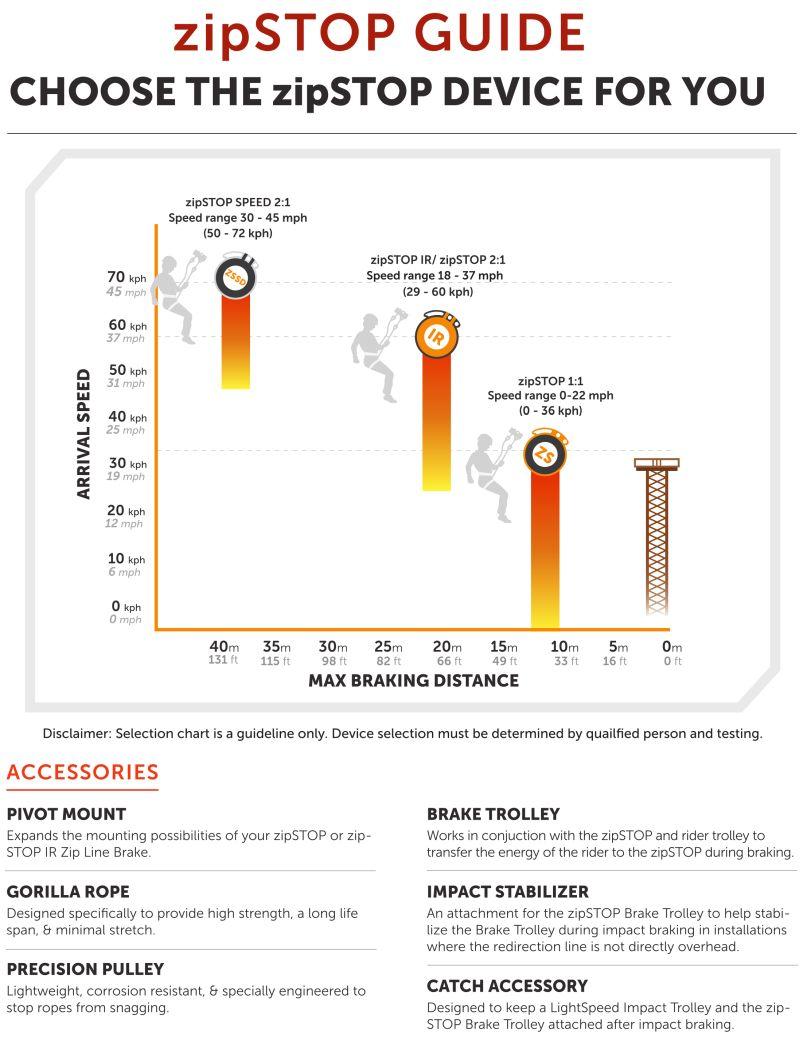

How to select the right zipSTOP Device for your zipline setup

Select device model/reduction ratio which has a maximum device speed higher than the maximum arrival speed in all conditions. Maximum device speed must be sufficiently higher than maximum arrival speed to account for variability and other factors.

- Max Arrival Speed < 36 kph [22 mph] -> zipSTOP 1:1

- Max Arrival Speed < 60 kph [37 mph] -> zipSTOP IR, zipSTOP 2:1

- Max Arrival Speed < 72 kph [45 mph] -> zipSTOP SPEED 2:1

Expert FAQ

Q: How does the zipSTOP SPEED differ from the zipSTOP IR?

A: While both use magnetic braking, the zipSTOP SPEED is geared specifically for higher velocities (up to 72 kph). It features an internal reduction gear and requires an external 2:1 line setup. The zipSTOP IR is designed for speeds up to 60 kph and does not use an external reduction line.

Q: Can I use the zipSTOP SPEED with a 1:1 direct line setup?

A: No. The zipSTOP SPEED (Model ZSSD150-20A) is strictly engineered for a 2:1 reduction configuration. Using it in a 1:1 setup would exceed the device’s retraction velocity limits and compromise braking performance.

Q: What is the “Cost of Ownership” implication for this device?

A: The primary costs are the annual recertification fee and the replacement of the webbing line, which depends on throughput volume. Because there are no friction pads or internal mechanical wear parts involved in the braking force, catastrophic mechanical failure is extremely rare, resulting in a predictable and low long-term operational cost.

Q: Does the device require electricity?

A: No. The eddy current braking relies on the laws of physics (Lenz’s Law) generated by the movement of magnets past a conductive surface. It operates entirely without external power, ensuring safety even during power outages.