Description

Achieving consistent deceleration across variable rider weights is the primary engineering challenge for commercial ziplines. The zipSTOP IR Zip Line Brake solves this via eddy current magnetic braking, ensuring a soft catch for a 15 kg child or a 150 kg adult without manual intervention. As the industry standard for “average” to high-speed lines, the IR model integrates a mechanical 2:1 reduction system directly into the unit, offering the braking power required for faster lines in a compact, weather-resistant chassis.

Ideal Applications

High-Throughput Adventure Parks: Automated reset allows for rapid rider cycling.

Mid-to-High Velocity Ziplines: Specifically engineered for arrival speeds between 24–60 kph (15–37 mph).

Compact Platform Designs: Internal reduction eliminates the need for long external reduction line rigging, saving tower space.

Variable Rider Demographics: Self-regulating resistance accommodates weights from 15 kg (33 lbs) to 150 kg (330 lbs).

Technical Specifications

Certifications & Standards:

ASTM F2959: Standard Practice for Aerial Adventure Courses.

ASTM F24: Amusement Rides and Devices.

EN 15567-1: Sports and Recreational Facilities (Component compliant).

ISO 17025: Tested in accredited laboratories.

Braking Mechanism: Self-regulating Eddy Current (Magnetic Induction).

Reduction Ratio: Internal 2:1 (Mechanical).

Operational Velocity: 0 – 60 kph (0 – 37 mph).

Rated Working Capacity (WLL): 15 – 150 kg (33 – 330 lbs).

Device Weight: 23.5 kg (52 lbs).

Line Specifications: 20 mm Nylon/Spectra webbing (Field Replaceable).

Maximum Line Extension: 20 m (65.6 ft).

Environmental Rating: Weather-resistant aluminum alloy casing; zinc-plated steel internal components.

Operational Efficiency & Engineering

The zipSTOP IR is defined by its Internal Reduction (IR) architecture. Standard magnetic brakes often require “external reduction lines” (a system of pulleys and ropes) to handle speeds above 36 kph. The IR model miniaturizes this physics advantage inside the unit.

Throughput: The braking line automatically retracts after rider dismount, resetting the system instantly for the next user.

Magnetic Reliability: With no contacting friction pads to burn out or glaze, braking performance remains consistent regardless of rain, heat, or dust.

Redundancy Ready: Designed to function as a primary brake, seamlessly integrating with Emergency Arrest Devices (EAD) for a fail-safe system.

Maintenance & Lifecycle

Designed for high ROI, the zipSTOP IR minimizes “cost of ownership” through non-sacrificial braking components.

Friction-Free: The core magnetic braking module has no contacting parts, virtually eliminating wear on the braking engine itself.

Service Intervals: Requires annual recertification to ensure calibration and safety compliance.

Field Serviceability: The sacrificial webbing (“braking line”) and bumper are the only frequent wear parts and can be replaced on-site by trained staff, minimizing operational downtime.

Zipstop Annual Service

To maintain your zipSTOP IR Zip Line Brake warranty and ensure compliance with safety standards, all devices must undergo an annual service. Service is an annual process to make sure that your zipSTOP IR is operating properly and any worn parts, like the webbing, are replaced. Servicing your zipSTOP IR on time helps to maintain the warranty and maximize performance. Annual service is also mandatory to ensure compliance with safety standards like CE and ANSI. Check the zipSTOP IR Annual Service fee.

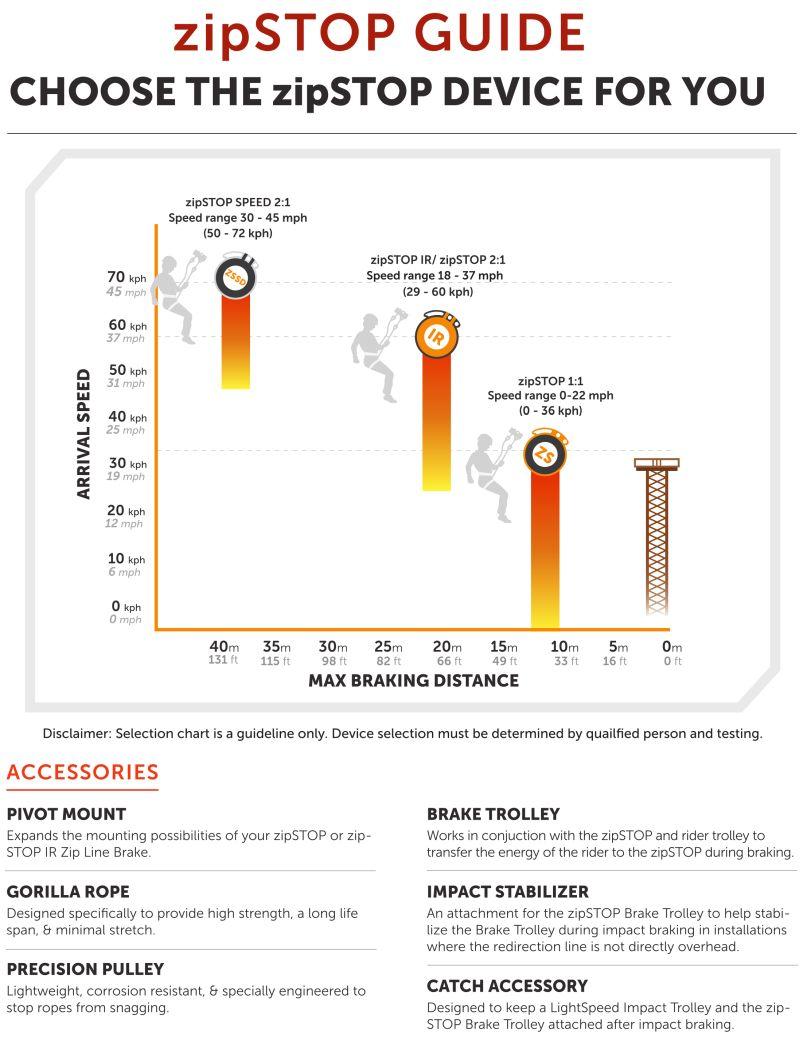

How to select the right zipSTOP Device for your zipline setup

Select device model/reduction ratio which has a maximum device speed higher than the maximum arrival speed in all conditions. Maximum device speed must be sufficiently higher than maximum arrival speed to account for variability and other factors.

- Max Arrival Speed < 36 kph [22 mph] -> zipSTOP 1:1

- Max Arrival Speed < 60 kph [37 mph] -> zipSTOP IR, zipSTOP 2:1

- Max Arrival Speed < 72 kph [45 mph] -> zipSTOP SPEED 2:1

Expert FAQ

Q: How does the Internal Reduction (IR) affect installation compared to the standard zipSTOP?

A: The IR model houses the 2:1 mechanical advantage inside the casing. This removes the need to design and rig an external reduction line system (pulleys and counterweights) on your tower, simplifying the install footprint and reducing the number of external components to inspect.

Q: Can the zipSTOP IR be used with an external reduction line to handle even higher speeds?

A: No. The zipSTOP IR is engineered specifically as a standalone 2:1 system. Adding external reduction lines is prohibited. For speeds exceeding 60 kph (37 mph), the zipSTOP SPEED model should be specified.

Q: Is the braking distance static for all riders?

A: No, but it is controlled. The eddy current resistance scales with velocity. While heavier riders will travel slightly further into the braking zone than lighter riders, the deceleration force is self-regulated to keep g-forces comfortable and safe for both.

Q: What is the mandatory service schedule?

A: The device must undergo a manufacturer or authorized service center recertification annually (every 12 months). The webbing assembly should be inspected daily and replaced immediately upon showing signs of wear or after a set number of cycles, whichever comes first.