Description

For professional adventure park operators, inconsistent braking is a liability that compromises safety and throughput. The Head Rush Technologies zipSTOP Zip Line Brake solves this by replacing mechanical friction with advanced eddy current magnetic technology. As the industry-standard solution, it provides a consistent, self-regulating braking experience for riders from 15 kg to 150 kg, drastically reducing maintenance downtime and liability risks associated with rider impact.

Ideal Applications

High-Throughput Adventure Parks: Automated reset allows for rapid rider intervals.

Canopy Tours & Ziplines: Primary braking for lines with arrival speeds up to 36 kph (22 mph) [1:1 ratio].

Course Terminations: Ideal for platforms requiring precise, low-g deceleration.

Variable Rider Groups: Automatically adjusts to weight variances without staff intervention.

Technical Specifications

Certifications: ASTM F2959-18, Consensus Standard for Aerial Adventure Courses; Tested in ISO 17025 accredited labs.

Rated Working Capacity: 15 – 150 kg (33 – 330 lbs).

Rated Working Velocity (1:1): 0 – 36 kph (4 – 22 mph).

Rated Working Velocity (2:1): 0 – 60 kph (6 – 37 mph) [Requires reduction line assembly].

Device Dimensions: 80 mm x 320 mm x 216 mm (3.15 x 12.6 x 8.5 in).

Device Weight: 23.5 kg (52 lbs).

Braking Line Extension: Max 12.5 m (41 ft).

Material Construction: Aluminum alloy housing, zinc-plated steel internal components, weather-resistant design.

Operational Efficiency & Engineering

The zipSTOP utilizes Eddy Current Magnetic Braking, a non-contact technology where braking resistance is generated by the movement of a conductive surface through a magnetic field. This system is self-regulating: the faster a rider arrives or the heavier they are, the more resistance is applied, ensuring a comfortable deceleration distance every time.

Throughput Optimization: The unit automatically resets the braking line after each rider dismounts, minimizing guide interaction and allowing for higher riders-per-hour (RPH).

Redundancy: Designed as a primary brake, it integrates seamlessly with emergency arrest devices (EAD) to create a fail-safe termination system.

Consistency: Unlike friction pads that change characteristics when wet or hot, magnetic braking performance remains stable in rain, heat, and cold.

Zipstop Annual Service

To maintain your zipSTOP Zip Line Brake warranty and ensure compliance with safety standards, all devices must undergo an annual service. Service is an annual process to make sure that your zipSTOP is operating properly and any worn parts, like the webbing, are replaced. Servicing your zipSTOP on time helps to maintain the warranty and maximize performance. Annual service is also mandatory to ensure compliance with safety standards like CE and ANSI. Check the zipSTOP Annual Service fee.

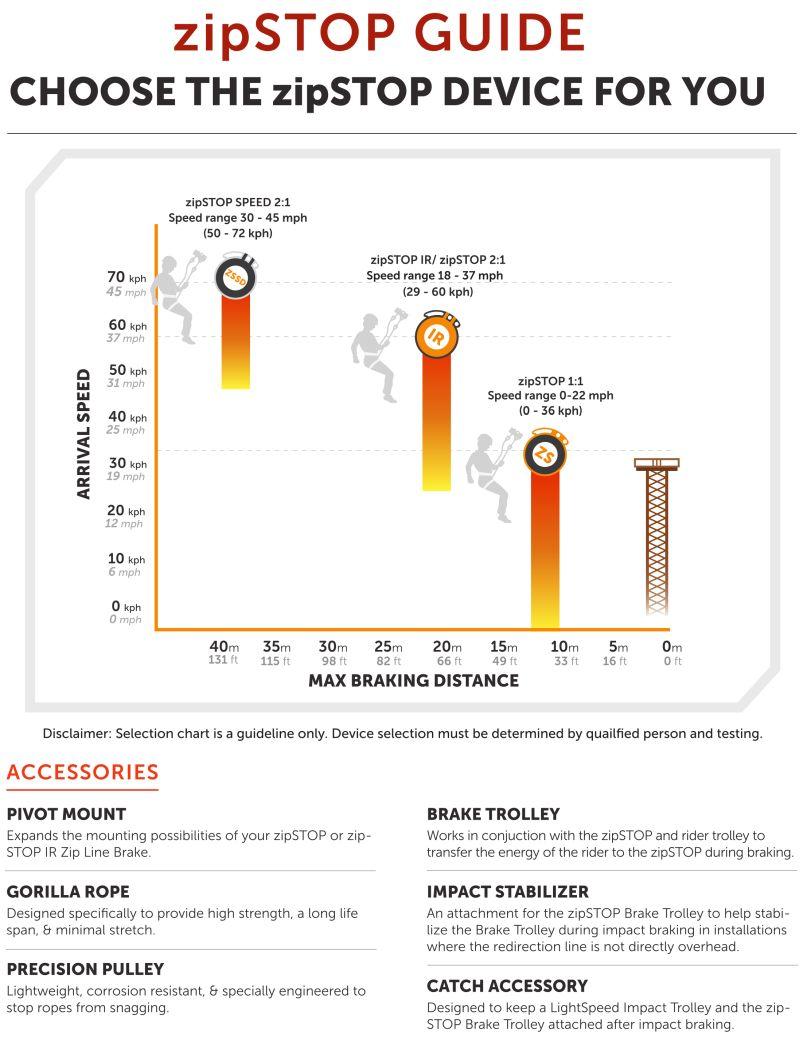

How to select the right zipSTOP Device for your zipline setup

Select device model/reduction ratio which has a maximum device speed higher than the maximum arrival speed in all conditions. Maximum device speed must be sufficiently higher than maximum arrival speed to account for variability and other factors.

- Max Arrival Speed < 36 kph [22 mph] -> zipSTOP 1:1

- Max Arrival Speed < 60 kph [37 mph] -> zipSTOP IR, zipSTOP 2:1

- Max Arrival Speed < 72 kph [45 mph] -> zipSTOP SPEED 2:1

Maintenance & Lifecycle

Investing in zipSTOP lowers the Total Cost of Ownership (TCO) through reduced consumable dependency.

No Friction Pads: The magnetic system is contactless, eliminating the daily wear associated with pad-based brakes.

Service Intervals: Annual recertification (every 12 months after the initial 15-month period) ensures long-term compliance and warranty validity.

Field-Replaceable Parts: The braking webbing and bumper are designed for easy field inspection and replacement by competent personnel, minimizing operational downtime.

Expert FAQ

Q: Can the zipSTOP be used as the sole braking device on a zipline?

A: No. While the zipSTOP is a highly reliable primary brake, industry standards (such as ACCT and ASTM) require the use of an independent Emergency Arrest Device (EAD) to ensure rider safety in the event of a primary system failure.

Q: How does the 2:1 reduction line configuration affect the device’s performance?

A: A 2:1 configuration effectively doubles the braking capacity, allowing for higher arrival speeds up to 60 kph (37 mph). This setup routes the line through a pulley on the brake trolley and anchors it back near the device, halving the line extension speed relative to the rider.

Q: Is the braking force adjustable for different rider weights?

A: The braking force is self-regulating via eddy current physics. You do not need to manually adjust the device for different weights; the magnetic resistance increases proportionally with the velocity and mass of the rider to maintain a safe deceleration rate.

Q: What is the maximum line extension and how does it impact brake zone design?

A: The maximum line extension is 12.5 m (41 ft). Engineers must calculate the “brake zone” length to accommodate this full extension plus a safety buffer, ensuring the rider never impacts the device or the end anchor structure.