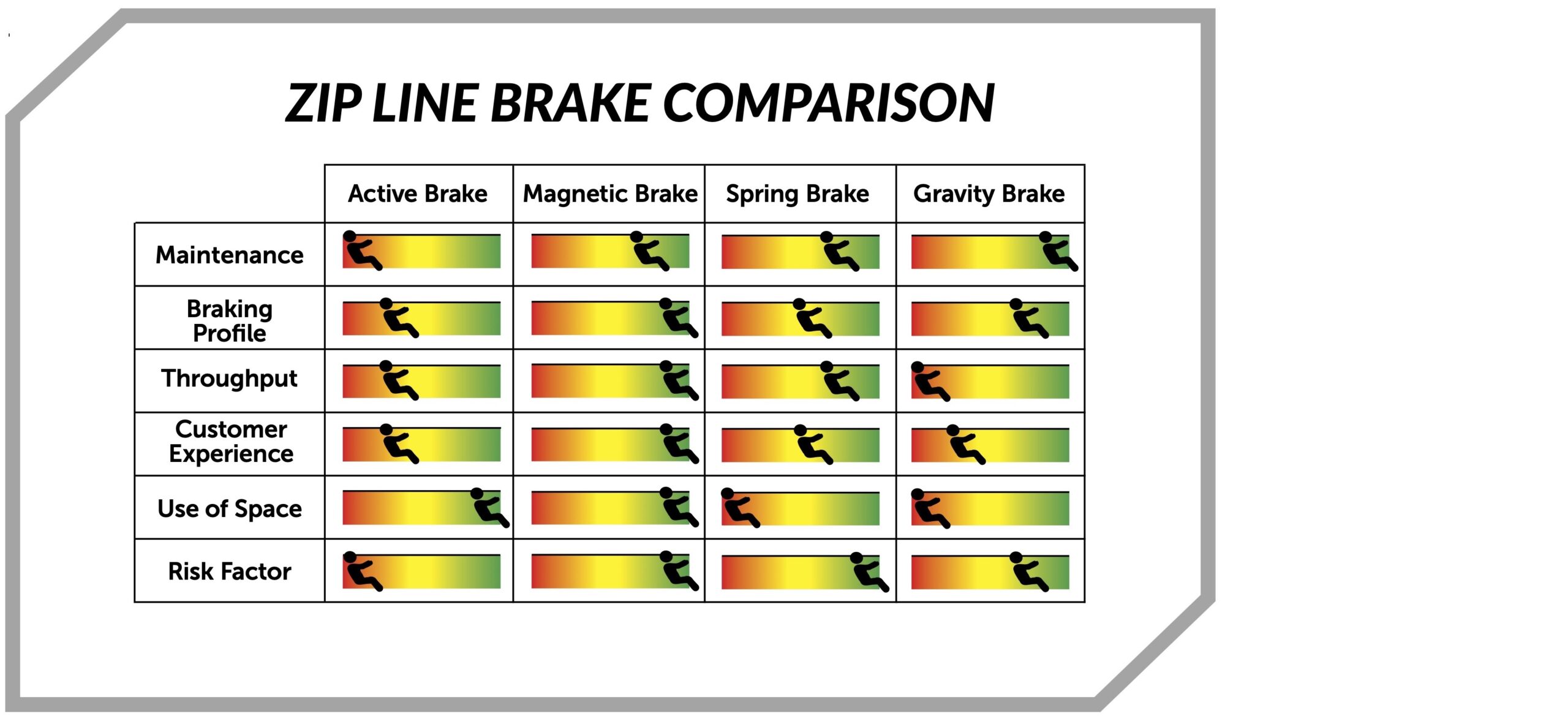

Choosing the right zip line brakes is a critical decision that impacts your operations, revenue, and risk management. This buyer’s guide provides a detailed comparison of the four most common types of braking systems to help you make an informed choice. We evaluate active brakes, which rely on human intervention, alongside three passive systems: magnetic, spring, and gravity brakes. Each system is analyzed based on essential factors including maintenance requirements, rider throughput, customer experience, use of space, and overall risk. Understand the pros and cons of each method to select the best zip line brakes for your course design and business goals.

Active and passive zip line brakes are the two most common types. Human intervention is required to begin and regulate the braking process with active zip line brakes. Passive zip line brakes, such as magnetic, spring, and gravity braking, operate automatically without the rider or guide having to do anything. Let’s start with a quick comparison of how each braking method performs in each category to help you choose the proper zip line brake for your project.

ACTIVE BRAKING

Active zip line brakes rely on friction and human intervention. The rider uses leather gloves or a brake pad to apply a normal active brake. Staff can also use friction-based redirection or belay systems to operate active brakes.

Active zip line brakes rely on friction and human intervention. The rider uses leather gloves or a brake pad to apply a normal active brake. Staff can also use friction-based redirection or belay systems to operate active brakes.

Maintenance

Due to the amount of friction needed to slow riders, on higher speed lines this type of system will require a lot of equipment maintenance and replacement.

Braking Profile

Because participants are in charge of braking themselves in an active braking system, the braking resistance and experience can be highly variable.

Throughput

If the rider or operator brakes too early or aggressively in an active braking system, they may not make it to the platform. When this happens, the entire group must wait for them to haul themselves to the end of the line or be retrieved by a staff member. Premature braking is a detriment to the efficiency of zip line operations.

Customer Experience

While active brakes may give riders and staff more participation in the experience, the likelihood of distraction or misapplication of the brake increases. This can have a negative effect on the customer’s overall experience.

Use Of Space

Active braking is a very efficient use of space; however, maximum speeds must be kept to a minimum or lines must have a large runout to allow room for participants to actively brake and control their speeds.

Risk Factor

For a variety of reasons, active brakes can significantly raise the risk of damage to players. It’s easy for participants to get caught up in the thrill of the moment and forget about the braking instructions. Furthermore, active brakes force the rider’s hands and limbs to be near to fast-moving zip line components. The danger of a participant receiving a friction burn on an exposed portion of skin or injuring their hand by getting it trapped in the passenger trolley increases simply because of proximity. When it comes to active brakes, these are among the least serious injuries that can occur. The most serious injuries that can result from active brakes are life-threatening.

-

Product on sale

zipSTOP SPEED | High-Velocity Magnetic Braking SystemPrice range: € 6.198,00 through € 6.455,00 Ex VAT

zipSTOP SPEED | High-Velocity Magnetic Braking SystemPrice range: € 6.198,00 through € 6.455,00 Ex VAT -

Product on sale

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT -

Product on sale

zipSTOP Zip Line Brake | Magnetic Braking SystemPrice range: € 5.334,00 through € 5.538,00 Ex VAT

zipSTOP Zip Line Brake | Magnetic Braking SystemPrice range: € 5.334,00 through € 5.538,00 Ex VAT

PASSIVE MAGNETIC BRAKING

The zipSTOP Zip Line Brake is a tier of passive zip line brakes all its own. The zipSTOP is the only magnetic braking zip line brake on the market. Magnetic braking works by using centrifugal force to create eddy currents that oppose the magnets’ force, producing resistance and slowing the rider down. Magnetic braking delivers unequaled cyclic endurance to conduct ride after ride because it is friction-free and has no touching elements.

Maintenance

The use of eddy current magnetic braking technology eliminates the need for sacrificial braking components. Since there are no brake pads or any internal braking parts that rely on friction, the zipSTOP is long-lasting and needs less maintenance than friction-based brakes. It should be noted that because the zipSTOP is a life-safety device it must undergo a check-up by an authorized service center every year.

Braking Profile

A 33lb child and a 330lb football player will both experience the same comfortable deceleration thanks to the magnetic brakes found in the zipSTOP. This self-regulating design enables a smooth and consistent brake regardless of rider weight and speed.

Throughput

Magnetic braking is incredible for improving throughput. The zipSTOP automatically resets after every use so the brake is always ready for the next participant to descend. The throughput efficiency of the zipSTOP can be further enhanced when it is combined with other zip line accessories.

Customer Experience

Thanks to the zipSTOP’s magnetic braking technology zip line operators can provide the same high-quality zip line experience to every participant regardless of weight. Plus, because the zipSTOP brakes for riders, that means less stress for riders and staff. The automatic reset reduces downtime too. This all adds up to more happy customers.

Use Of Space

Passive magnetic braking is unique in the fact that it automatically adjusts braking force based on rider size and speed, resets by itself and does not use friction to provide resistance so it’s unaffected by environmental conditions.

Risk Factor

Automatic brake regulation and reset minimizes chances for human error and allows riders and guides to be more engaged in the experience.

PASSIVE SPRING BRAKING

Spring brakes were among the first passive brakes invented. To generate an effective brake for incoming riders, long banks of springs are placed together. To smooth out the catch, some may utilize progressive spring rates at the sacrifice of space, while others may use a set spring rate that is shorter but harsher. The majority of spring brakes are permanently installed near the line’s terminal, while some are housed elsewhere and activated by redirection ropes.

Maintenance

While spring brakes are fairly simple mechanical systems, regular inspection is still needed. In certain environments corrosion will have to be evaluated regularly, as will the condition of padding which degrades in harsh environmental conditions. It is also worth noting that a full zip line inspection must be conducted where the springs move back and forth, which can be difficult based on limited access to the cable which is blocked by springs or may be detached from platform access.

Braking Profile

Different weight riders will have different braking experiences with spring brakes. Heavier riders are going to cause more spring compression and will rebound further. Lightweight riders will compress the spring less and will experience a more abrupt stop than heavier riders. This wide range of possible outcomes is magnified by environmental conditions leading to variable arrival speeds.

Throughput

Conventional spring brakes decompress and then push the rider back out in the direction they came from to bring them to a stop. Every second that a customer spends rebounding is a second that you could be using to get another customer through the course. These seemingly small inefficiencies quickly add up and make a significant impact on throughput.

Customer Experience

A variable braking experience and time spent bouncing around at the end of the line can mean lower levels of customer satisfaction for zip lines using passive spring braking.

Use Of Space

Unlike most other zip line brakes, springs do not move on the line and cannot be moved out of the way. Large spring banks are permanently installed on the zip line, necessitating very large platforms or detached terminal structures. It is also necessary with standard spring brakes to have a high-tension zip line with a downhill slope all the way to the termination point, which can lead to increased build cost and maintenance over time.

Risk Factor

Springs are generally set up with many internal redundancies and, unless otherwise arranged, automatically reset after use. For this reason, they are very reliable, however care must be taken to avoid contact with the metal coils or properly pad the brake while still allowing inspection.

PASSIVE GRAVITY BRAKING

A gravity zip line will be very loose and nearly match termination heights at both ends in the most traditional sense. Before reaching the termination end, the cyclist will accelerate swiftly, then climb back up the loose rope and decelerate. The rider will then pendulum back and forth until they reach the lowest point, where they will be removed via a ladder or similar technique. Many zip lines will rely on a combination of gravity and various types of brakes.

Maintenance

Gravity brakes are in fact the absence of any brake system, so there is no maintenance needed on the brake system itself.

Braking Profile

While gravity is a constant force and always reliable, it tends to be a less desirable braking method because of the time lost waiting for participants to come to a stop.

Throughput

The main drawback of gravity brakes is their low throughput. It takes time for a participant to ricochet back and forth enough to come to a stop. That time could be better spent sending another rider down the line.

Customer Experience

Rolling back and forth to slow down is the least appealing part of zip lining. The time it takes waiting for a gravity brake to slow a participant doesn’t add value for the customer. Riders would rather spend less time waiting and more time zipping.

Use Of Space

Gravity brakes require that a portion of the cable be dedicated to braking, which means that a portion of the cable and a portion of your facility is effectively being unused. This inefficient use of space makes for another frustrating shortcoming of gravity brakes.

Risk Factor

Gravity never fails, so a well-built gravity zipline is 100% effective in arresting rider motion. Risks can be introduced via hazards on the line or in the zip path due to the low throughput and use of ladders or other means to unload participants after riding.

SUMMARY

Active braking, passive magnetic braking, passive spring braking, and passive gravity braking are the four most frequent forms of zip line brakes. Zip line brakes that are passive are superior to active zip line brakes. The fundamental advantage of passive zip line brakes is that they reduce the possibility of players injuring themselves by braking incorrectly. Because of its automatic regulating and resetting, the zipSTOP is the most advanced self-contained zip line braking unit on the market among passive zip line brakes. The zipSTOP is made to last season after season on the world’s greatest throughput zip lines, thanks to wear-free eddy current magnetic braking technology.

Want to speak to a member of our team about outfitting your zip line course with zipSTOP Zip Line Brakes? Get in touch here.

Zipwire braking systems

We offer a full family of zip line brakes that increase throughput with a hands-free braking experience for zip line riders and operators, and a full ecosystem of zip line products to outfit the best zip line builds in the world.

We utilize our patented eddy current magnetic braking technology to create a comfortable braking experience. Magnetic eddy current braking is extremely reliable and low maintenance due to no contacting parts in the braking system.

Beyond the Basics: Unveiling Zipline Technology with Expert Analysis

Intrigued by the potential of Zipline technology? You’ve come to the right place! This article provides a solid foundation. But if you’re eager to delve deeper and gain insights from industry experts, keep reading…

- Two-Way Adventure: Bi-Directional Zipline Trolley Solutions

- Considering operating and investing in a zipline?

- 9 Zipline Mistakes You Don’t Know You’re Making

- Magnetic Zipline Braking: A Revolutionary Way to Ensure Safe Rides

- Pros and Cons of Different Zip Line Brakes

- Maximizing Zip Wire Park Revenue with a Speed-regulating zipline trolley

- White Paper on Zipline Emergency Arrest Devices (EAD)

- The Importance of Optimizing Zip Line Design for Rider Speed

- Does your zip line need an emergency arrest device?

- The Magnetic Self-braking Zipline pulley

- Zipline Braking and landing considerations

- Why Zip Line Trolley Bearings Matter

- Whitepaper: Zipline Braking Dynamics

- Zip Line Installation: Give them the Best Ride

- How to startup a Successful Zip Line Business

-

Zipline Spring Brake System | Primary & EAD Braking€ 80,00 Ex VAT

Zipline Spring Brake System | Primary & EAD Braking€ 80,00 Ex VAT -

Product on sale

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT -

Product on sale

zipSTOP SPEED | High-Velocity Magnetic Braking SystemPrice range: € 6.198,00 through € 6.455,00 Ex VAT

zipSTOP SPEED | High-Velocity Magnetic Braking SystemPrice range: € 6.198,00 through € 6.455,00 Ex VAT