Description

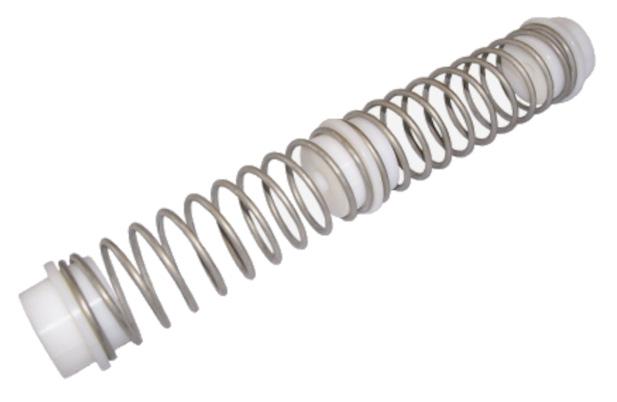

When rider safety is non-negotiable, you need a zipline braking system that performs every time. This modular spring brake is engineered for the demands of commercial operations, functioning flawlessly as a primary brake or a fail-safe Emergency Arrest Device (EAD). Built from corrosion-resistant materials and tested for high-speed impacts, it provides the consistent, smooth deceleration necessary to ensure a safe and positive guest experience on your course.

Full Specifications

- Application: Primary Brake & Secondary Emergency Arrest Device (EAD)

- Maximum Tested Speed: 80 km/h

- Materials: Corrosion-resistant stainless steel springs, durable nylon spacer blocks

- Modular Component: Each section includes one spring and one nylon spacer

- Component Length: Approximately 30 cm per section

- Installation: Easily retrofittable onto existing zipline cables

- Maintenance: Minimal maintenance required

As an example the following calculation for the size of the spring-pack:

Incoming speed (km/h) | 25 | |

| Spring brake used as: | Primary Brake | Secondary Brake EAD |

| Springs needed | 20 | 15 |

| Spacers needed | 21 | 16 |

| Spring-pack length (meter) | 6,4 | 4,8 |

Uncompromising Safety, Unmatched Reliability

In the world of commercial ziplines, braking failure is not an option. Our zipline spring brake is designed as the core of a truly redundant safety system. Use it as a robust primary brake for consistent, smooth stops or as an essential emergency arrest device for zipline courses where the primary system fails. This dual-purpose capability streamlines your component inventory and simplifies safety protocols, providing reliable stopping power you can count on for every rider, run after run.

Modular Design for Precision Braking

No two ziplines are identical. Your specific operational parameters—including arrival speed and your facility’s rider weight range—demand a tailored braking solution. This system’s modular design allows you to create the perfect high-speed zipline brake by precisely tuning its length and force. We work with you to configure a system based on your lightest and heaviest expected riders, not a generic “average” weight. This ensures every participant experiences a safe, comfortable, and predictable deceleration, protecting both your guests and your equipment.

How to install the springs on the zipwire?

Frequently Asked Questions

Q: How do I determine the correct number of springs for my zipline?

The required number of springs is determined by a custom calculation based on your zipline’s specific profile. We analyze your rider arrival speed, cable slope, and crucially, the full operational weight range of your riders (lightest to heaviest) to engineer the optimal configuration for your course.

Q: Can this system function as both a primary brake and a zipline EAD?

Yes. It is engineered and tested to perform reliably as a standalone primary brake or as a secondary emergency arrest device zipline (EAD).

Q: Is the brake system weather-resistant?

Absolutely. The system is constructed from stainless steel springs and high-durability nylon spacers, making it highly resistant to corrosion and UV degradation in outdoor environments.

Q: What routine maintenance is required?

The system requires minimal maintenance. We recommend regular visual inspections for wear and to ensure all components are secure as part of your standard course inspection protocol.

Q: Does this system comply with industry safety standards?

When correctly configured based on our expert consultation, this system helps you meet emergency braking requirements according to EN, ACCT, and ASTM standards.

Expert Information regarding Zipline technology

Interested to read more about Zipline technology and Expert opinions?

- Zip Line Design: Components for a Complete System

- Considering operating and investing in a zipline?

- 9 Zipline Mistakes You Don’t Know You’re Making

- Magnetic Zipline Braking: A Revolutionary Way to Ensure Safe Rides

- Pros and Cons of Different Zip Line Brakes

- Expert Tips for Zip Line Brake Installations

- White Paper on Zipline Emergency Arrest Devices (EAD)

- The Importance of Optimizing Zip Line Design for Rider Speed

- Does your zip line need an emergency arrest device?