A Zipline Emergency Arrest Device (EAD) is a critical safety component designed to stop a rider if the primary brake fails, preventing serious injury or death. This comprehensive guide explores the definition and requirements for EADs according to key industry standards, including the Association for Challenge Course Technology (ACCT) and the American Society for Testing and Materials (ASTM). You’ll learn when an EAD is mandatory, how to properly measure arrival speeds to assess your needs, and review practical examples of compliant EADs like spring packs and dual zipSTOP systems. We also identify common methods, such as tires or prusik knots, that do not qualify as safe emergency brakes, ensuring your operation meets the highest safety standards.

The definitions of Zipline Emergency Arrest Device varies between standards:

- Thrill Syndicate refers to emergency brakes and fail-safe braking systems as EADs.

- ACCT refers to EADs as an emergency brake.

- ASTM refers to brake systems as fail-safe and does not use the phrase EAD or emergency brake.

Zipline EADs According to ASTM

A direct definition of an emergency brake or EAD is not provided in ASTM 2959. The term EAD, or emergency brake, isn’t even mentioned. Instead, according to ASTM 2959, all braking devices on a zip line must be fail-safe. To be fail-safe, a brake system must be “built in such a way that the normal and expected failure mode results in a safe condition.” If a possible failure mode in the braking system exists, an addition to the brake system that creates a safe state for the participant must be made.

- ASTM Definition of Brake System: As it applies to aerial adventure courses, examples of braking systems include, but are not limited to: longitudinal friction brakes, disc or drum brakes, motor end brakes, either onboard or off-board of the patron-carrying vehicle or device. If the failure of the braking system results in an unsafe condition, then the braking system shall be fail-safe.

- ASTM Definition of Fail-Safe: Characteristic of an aerial adventure course, or component thereof, that is designed such that the normal and expected failure mode results in a safe condition.

Zipline EADs According to ACCT

Zip lines must include both a primary braking system and an EAD to ensure riders are stopped safely, effectively, and reliably at the end of the line, according to ACCT guidelines. An EAD is required as a backup for all zip lines where a participant arrives at the landing area at speeds greater than 6 mph (10 kph) and where a participant may come into unintended and/or harmful contact with terrain, objects, or people in the landing area, according to the ANSI/ACCT 03-2016 standard. Such a device must not require the participant’s activity to engage, must avoid harm or death, and must engage independently of the primary brake.

- ACCT Definition of Emergency Brake: A brake located on a zip line that engages without any participant input upon failure of the primary brake in order to “prevent serious injury or death”.

- ACCT Clarification on Emergency Brake: On zip lines that require an emergency brake, the emergency brake function may be integrated into the primary brake system as long as it acts independently from the primary brake.

-

Zipline Airbag | EAD (Emergency Arrest Device)€ 2.500,00 Ex VAT

Zipline Airbag | EAD (Emergency Arrest Device)€ 2.500,00 Ex VAT -

Zipline Spring Brake System | Primary & EAD Braking€ 80,00 Ex VAT

Zipline Spring Brake System | Primary & EAD Braking€ 80,00 Ex VAT -

Product on sale

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT

When is an Zipline Emergency Arrest Device required?

When is an Zip Line EAD Required According to ASTM

In order to understand the requirements of ASTM, we must first understand a failure analysis.

A failure analysis, according to ASTM 2291, is a documented assessment which, “identifies the most significant factors of a zip line that may affect patron safety and shall include mitigation for each factor.” Simply put, a failure analysis is a required document that states all possible items that could go wrong within the zip line and what has been done to mitigate the consequences. There is no question that a zip line’s brake system has the potential to affect patron safety. Therefore, a failure analysis of a brake system must be completed by the designer/engineer of the zip line in order to meet ASTM standards.

During the failure analysis of the brake system, the designer/engineer of the zip line will most likely find that a certain aspect of the brake system has a normal and expected failure mode. If the failure mode results in an unsafe condition for the patron (e.g. hitting the termination pole of the zip line), another aspect must be added to the brake system

in order to mitigate the potential for patron injury and ensure a fail-safe brake system.

ASTM 1193 states a requirement for Performance and Operational Testing that must be completed by the designer/engineer:

- ASTM 1193: Performance Testing – this should consist of a series of specified tests that can be used to determine that the newly erected ride or device conforms to the original design criteria.

- ASTM 1193: Operational Testing – the manufacturer of an aerial adventure course shall develop specific operational tests along with minimum intervals for these tests to be performed that will allow the owner/operator of the aerial adventure course to determine whether a given ride or device is operating within prescribed operational limits.

In accordance with ASTM 1193 the designer/engineer of the zip line must outline and perform a test procedure of the brake system that is based off the failure analysis document to ensure the brake system meets the fail-safe requirement. If a designer/engineer states that the zip line will meet ASTM standards, implying that the brake system will be fail-safe, they must perform testing to prove the installation meets such requirements.

When is an Zipline EAD Required According to ACCT

According to ACCT H.1.3 Emergency Brake Requirements: an emergency brake shall be required if, upon failure of the primary brake, both of the following may occur:

- The participant arrives at the zip line landing area at a speed in excess of 6 mph (10 kph)

- The participant experiences unintended and/or harmful contact with terrain, objects or people in the zip line landing area

In short, ACCT requires that the braking system is designed/engineered by the zip line installer, and that it incorporates an EAD for all zip lines where arrival speeds could be greater than 6 mph and the possibility of harmful contact within the landing area exists.

When is an Zipline EAD Required According to TS

All zipSTOP or zipSTOP IR installations, according to Thrill Syndicate (TS), should use an EAD. Any installation without an EAD that fulfills ACCT and ASTM criteria is forbidden from using a zipSTOP or zipSTOP IR. Guide activated EADs are discouraged by Head Rush, and they are included in our interpretation of the ACCT standard, which specifies that the EAD should not force the participant to take any action. Because guides are usually the first ones to descend a zip line, this is the case.

Furthermore, when a primary brake fails to engage, it usually happens rapidly, especially on high-speed lines, and a guide is unlikely to respond in time. As detailed in this white paper, the requirement originates from ASTM and ACCT standards.

-

ISC Zipspeed-S TrolleyPrice range: € 191,00 through € 283,00 Ex VAT

ISC Zipspeed-S TrolleyPrice range: € 191,00 through € 283,00 Ex VAT -

Self-braking Magnetic Zipline Trolley€ 1.320,00 Ex VAT

Self-braking Magnetic Zipline Trolley€ 1.320,00 Ex VAT -

Product on sale

LightSpeed Impact Zip Line TrolleyPrice range: € 189,00 through € 369,00 Ex VAT

LightSpeed Impact Zip Line TrolleyPrice range: € 189,00 through € 369,00 Ex VAT

Does my Zipline require an Emergency Arrest Device (EAD)?

According to ASTM

In order to meet ASTM Standards, the engineer/designer that built the zip line must produce a failure analysis, performance testing and operational testing document as outlined by ASTM 2291 and 1193. The documents provided by the engineer/designer of the zip line must state and prove that the brake system is fail-safe. If the brake system is not proven to be fail-safe by the engineer/designer, then additions must be made by the engineer/designer to ensure a fail-safe brake system.

According to ACCT

To determine if an EAD is required on a zip line two things must be done:

- Determine maximum arrival speed of a participant.

- Determine if it’s possible for a participant to experience unintended and/or harmful contact with the terrain, objects, or people in the zip line landing area.

Determining Maximum Arrival Speed

On a zip line, determining the maximum participant arrival speed is critical in determining whether an EAD is required. It is possible that if the procedure is not followed correctly and an EAD is not installed, the participant will be injured or die. Fortunately, determining maximum arrival speed is simple if the steps below are followed.

Environmental factors such as temperature, wind, and precipitation can all have a significant impact on participant arrival times. Changes in wind patterns, for example, can cause rider arrival speeds to fluctuate by 30 mph (48 kph). As a result, measuring arrival speeds is critical when the weather provides the best riding conditions for each zip line. Measure the arrival speed when there is a tail wind, for example, if a zip line experiences variable wind patterns.

In chilly weather, on a wet line, with a tail wind, a cyclist will travel the fastest. When the environment creates fast riding circumstances, it is critical to do arrival speed testing. Otherwise, the data recorded will not reflect the zip line’s maximum arrival speed, which could result in damage or death to participants.

Necessary Tools

- Radar Gun or other speed measuring device: Some options for radar guns are, Bushnell Velocity Speed Gun or an All Purpose Pocket Radar Gun. Other speed measuring devices are acceptable as long as the speed measured and

- recorded occurs immediately before braking is initiated.

- Weight bag(s) or sled capable of holding the minimum and maximum rider weight of the zip line.

- A rider trolley that is the same model as the trolley that will be used by the zip line participants.

Steps to Measure Arrival Speed

Important: Always perform unmanned testing to determine arrival speeds and to test any new or modified braking installations prior to sending individuals.

- An operator at the terminal end of the zip line will take and record arrival speeds using the radar gun. Attach the zip line’s minimum participant weight to the rider trolley at the beginning of the zip line.

- When the radar gun operator is ready, release the weight and rider trolley.

- As soon as the rider trolley and weight are visible to the operator, they should point the radar gun at the rider trolley and begin measuring the speed.

- Immediately before the rider trolley and weight engage the primary brake, the operator should evaluate and record the speed of the rider trolley.

- Increase the test weight by 100 lbs (45 kg) and repeat Step 2-5, and increase the weight by 100 lbs (45 kg) after each test until the zip line’s maximum participant weight is on the rider trolley.

- Once unmanned testing has been complete and all aspects of the zip line are working properly, repeat Steps 2-6 with participants of varying weights.

- Once all arrival speeds for the participant testing have been recorded, the highest of those values is the zip line’s “maximum arrival speed”.

When is a Zipline Emergency Arrest Device (EAD) not required?

According to ASTM

It is up to the engineer/designer that built the zip line to determine whether an EAD is necessary to ensure the brake system is fail-safe. If the engineer/designer determines, through failure analysis, performance testing and operational testing that the brake system is fail-safe without an EAD, than it may not be required.

According to ACCT

According to ACCT, there are two situations where an EAD may not be required. The first is if gravity is the sole braking method. The second is if arrival speeds, without any form of braking (other than gravity), are less than 6 mph (10 kph).

ACCT has outlined that when gravity and only gravity is used to brake the zip line participant and there is no chance of harmful contact, an EAD is not necessary.

- ACCT Appendix C states: “This [gravity] brake system is employed when at the end of the zip line traverse, the participant simply rolls back and forth in the belly of the zip line until coming to a stop. In this case, gravity is the only component of the primary brake, and if no possibility exists of striking anything during normal operations, the zip line will not require an emergency brake.”

ACCT also states that if the primary brake fails and arrival speeds are less than 6 mph (10 kph) that an EAD is not required. Head Rush would suggest considering conditions that exist, such as a tail wind, that could result in speeds greater than this, or if harmful contact with the terrain, objects or people is a possibility.

- According to ACCT H.1.3 Emergency Brake Requirements: an emergency brake shall be required if, upon failure of the primary brake, both of the following may occur:

- The participant arrives at the zip line landing area at a speed in excess of 6 mph (10 kph)

- The participant experiences unintended and/or harmful contact with terrain, objects or people in the zip line landing area

Zipwire Emergency Arrest Device examples

“A brake positioned on a zip line that operates without any participant input following failure of the primary brake in order to prevent significant damage or death,” according to ACCT.

Although Thrill Syndicate recognizes that certain EADs give greater braking than others, we do not recommend any specific type or brand of EAD. It is possible to adopt an EAD as long as it follows ACCT and ASTM criteria, has a fail-safe braking system, is assessed adequate by a certified professional, and delivers smooth and controlled participant deceleration. When planned, installed, and tested by a professional zip line designer/engineer, the following EAD instances have been shown to be practical.

Spring Pack

Spring packets have been discovered to be a successful EAD. A spring pack is made up of several springs that are about one foot long and are joined by plastic spacer blocks. The number of springs required for each zip line EAD is determined by rider arrival speed, weight range of riders, primary brake type, and other factors. Use only spring packs intended exclusively for braking zip lines. Do not attempt to utilize other materials as EAD springs. Designers/installers should check with zip line spring pack manufacturers to make sure the device is appropriately designed and installed to meet ACCT and ASTM standards for emergency braking.

A spring pack, when designed and fitted correctly, can help to build a fail-safe braking system. It will reliably and effectively bring a participant to a safe stop. Please be advised that an ASTM-certified spring pack with insufficient springs does not result in a fail-safe brake system. In a spring pack EAD, it’s usually better to overestimate the quantity of springs. If the rider uses too few springs, the spring pack may bottom out, resulting in injury or death.

Spring Pack Pros

- Provides smooth and effective emergency braking when the correct number of springs are used

- Easy to install, inspect, and maintain

- Corrosion resistant due to the stainless steel springs and plastic spacer blocks

- Easy to add or subtract springs to ensure proper EAD function

Spring Pack Cons

- May require longer landing zone. The length of a spring pack, when used as an EAD, can be up to 75 feet (23 meters) or longer. The actual length of the spring pack must be determined by the spring pack manufacturer and the designer/engineer of the zip line.

Magnetic Brake Trolley

Our Magnetic Brake Trolley is not an actual Zipline brake itself, but reduces the speed – depending on trolley configuration – of the zipline to a controllable speed at the end of the zipline. The self braking zip wire trolley solves the major safety issues around the controlled and safe braking situation at the end of high speed zip wire courses.

Due to the fact that we can reduce the speed of the zipline to a safe braking speed, the braking situation is less complex.

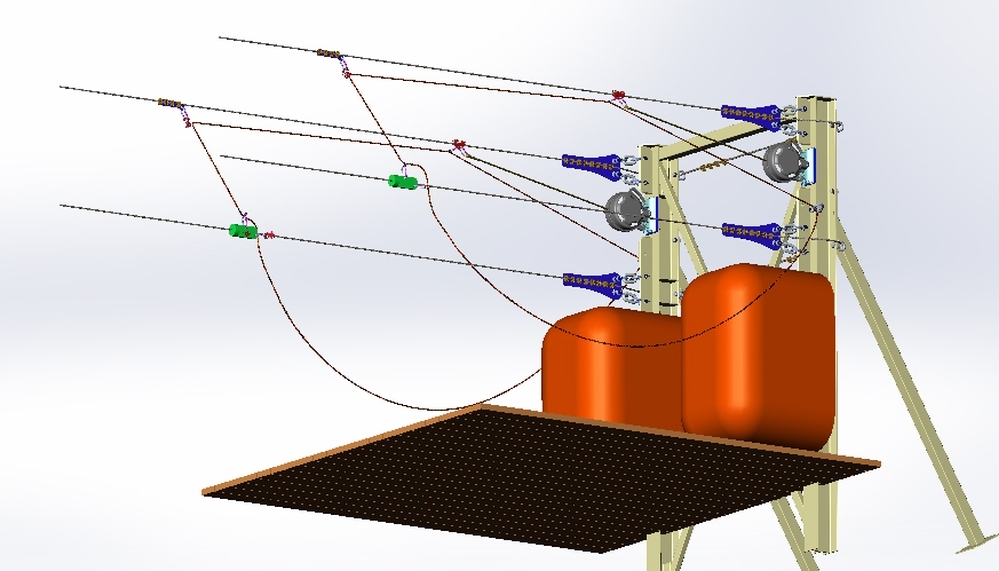

Example zipSTOP and Zipline Airbag

In the scenario below, the speed on a zipline with 25% descent was reduced to 15 kph arrival speed by using the Magnetic self braking zipline trolley. This allowed the use of a zipSTOP IR, in combination with the Zipline Airbag as Emergency Arrest Device . This setup is very helpful in (existing) situations where there is no space to place a Spring Pack.

Magnetic Brake Trolley/zipSTOP/Zipline Airbag Pros

- Suitable for (existing) situations with not enough space for a spring pack or dual zipSTOP configuration

- Meets both ACCT and ASTM standards

Magnetic Brake Trolley/zipSTOP/Zipline Airbag Cons

- Needs permanent 220V power supply at the Zipline Stop location

zipSTOP/zipSTOP IR

A zipSTOP/zipSTOP IR may be used as an EAD. The Brake Trolley used with the EAD (zipSTOP/zipSTOP IR) must have adequate room to provide full braking for the participant should the primary brake malfunction.

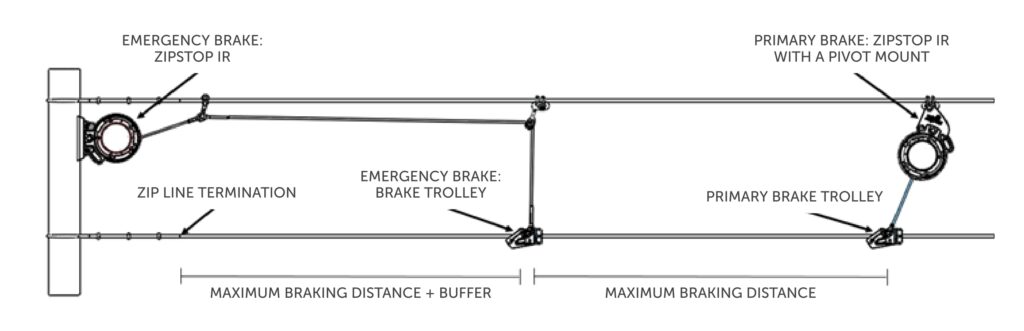

Example 1

A zipSTOP IR mounted with a Pivot Mount as the primary brake and a zipSTOP IR as the EAD is shown below. The EAD Brake Trolley must be installed the maximum braking distance from the primary brake trolley to ensure the EAD zipSTOP IR is not engaged during standard use. The maximum braking distance is the distance traveled by the brake trolley along the zip line to fully brake a participant during operation. With a hefty rider, on a chilly day, in a tail wind, the maximum braking distance will most likely occur. Prior to installing the zipSTOP IR EAD, the maximum braking distance must be checked and verified. To ensure that the participant does not engage the zip line termination point, the distance between the EAD Brake Trolley and the end of the zip line (zip line termination) must be the maximum braking distance Plus a buffer.

To ensure that the EAD Brake Trolley has enough area to go along the zip line in the event of emergency braking, the maximum braking distance + buffer is required. Please keep in mind that the image below is just one of many possible ways to set up a zipSTOP/zipSTOP IR as an EAD.

The ratio depicted above is for illustrative purposes only and should not be interpreted as how to properly install a zipSTOP or zipSTOP IR as a primary brake or EAD. All zipSTOP installations must be designed by a professional designer/ installer in accordance with the zipSTOP manual, ACCT and ASTM.

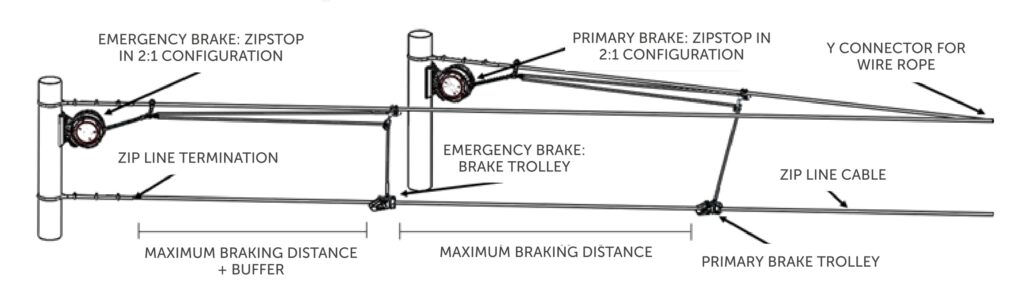

Example 2

Below is an image of a standard zipSTOP in a 2:1 configuration used as the primary brake and a standard zipSTOP in a 2:1 configuration used as the EAD.

The distance between the EAD Brake Trolley and the end of the zip line (zip line termination) must be the maximum braking distance + a buffer to ensure the participant will not engage the zip line termination point. The maximum braking distance + buffer is required to ensure that the EAD Brake Trolley has separate, adequate space to travel along the zip line in case of emergency braking. Please note that the below image is only one of multiple ways to install a zipSTOP/zipSTOP IR as an EAD.

The ratio depicted above is for illustrative purposes only and should not be interpreted as how to properly install a zipSTOP or zipSTOP IR as a primary brake or EAD. All zipSTOP installations must be designed by a professional designer/installer in accordance with the zipSTOP manual, ACCT and ASTM.

zipSTOP/zipSTOP IR Pros

- Provides smooth and effective emergency braking that will not result in rider swing up or impact with the zip line

- Meets both ACCT and ASTM standards

zipSTOP/zipSTOP IR Cons

- May require large landing platform

Zipline Brakes that are not Emergency Arrest Devices (EAD)

“A brake positioned on a zip line that operates without any participant input following failure of the primary brake in order to prevent significant damage or death,” according to ACCT. A brake system must, according to ASTM, “result in a safe condition.” There are methods to stop participants without their input if the primary brake fails, but they do not prevent injury or death, and they do not result in a safe condition. A list of stopping methods that are not regarded EADs and should not be employed is provided below.

Please note that these are just a few of the non-EAD brakes. Any other braking method that causes abrupt braking and may cause injury to participants should not be utilized as an EAD.

A single zipSTOP or zipSTOP IR

A zipSTOP or zipSTOP IR can be either a primary brake or an EAD, but a single zipSTOP CANNOT be both. According to the zipSTOP Manual:

- The zipSTOP is designed to be utilized as a Primary Brake or Emergency Arrest Device (EAD). When using the zipSTOP as a primary brake, the installer MUST utilize an independent EAD to protect against operator error and third party equipment failure. Design and installation of the zip line, including the complete braking system, is the responsibility of the installer or operator.

Inadequate Spring Pack

Spring packs have been found to be an effective EAD. However, a spring pack that is made up of too few springs does not meet ACCT or ASTM standards. For example, a spring pack that is not properly designed for the specific zip line may bottom out when engaged. The bottomed out spring pack may cause the rider to swing into the termination pole or other harmful object/terrain and result in serious injury or death.

It is the responsibility of the zip line designer/engineer to ensure that the spring pack EAD meets the requirements of the zip line spring pack manufacturer and is in accordance with ACCT and ASTM.

Hand Braking

According to ACCT Standards Appendix C: The hand brake is often accompanied with the effect of deceleration by gravity, so the two methods together, along with a proper level of instruction, could suffice as the primary brake in the system. Although hand braking can be considered part of a primary brake, it is NOT ever considered an EAD because it requires participant and/or operator input to engage. If a patron fails to hand brake, the resulting braking system will NOT result in a safe condition unless a proper EAD is implemented.

Prusik Knot

A prusik knot is NOT an EAD by ACCT or ASTM standards. A prusik knot, tied onto the zip line cable after the primary brake, is NOT an EAD because it may result in injury or death and does NOT result in a safe condition. When a participant engages a prusik knot, they may:

- Brake abruptly: which may result in the participant swinging into a harmful object or terrain. If a rider is traveling more than 6 mph (10 kph), it is possible that the swing up could result in injury or death.

- Not brake at all: which may result in the participant impacting the terminal structure.

- Brake in an unpredictable manner with varying results entirely dependent upon weather conditions, humidity, cable conditions, type-size-age of rope, etc.

Tire

A tire with a cable clamp holding the tire in place, mounted on the zip line cable, is NOT an EAD because it may result in injury or death and does NOT result in a safe condition. Therefore it does not comply with ACCT or ASTM standards. When a participant engages the tire, they will stop almost immediately, which may result in the participant swinging into a harmful object or terrain. If a rider is traveling more than 6 mph (10 kph), it is possible that the swing up could result in injury or death. A tire will degrade over time and when/if it degrades to the point of failure, a participant will break through the tire and hit the cable clamp directly.

Padding at Termination

According to ACCT Appendix C: It is generally understood that padding used as a protective element in the landing area does not constitute a brake component. A pad wrapped around the terminal pole of a zip line is NOT an EAD because impacting it may result in injury or death and it does NOT result in a safe condition. Therefore it does not comply with ACCT or ASTM standards.

Conclusion

The EAD, or emergency brake, is just as important as the primary brake in terms of reducing risk in a zip line operation.

An emergency brake, according to ACCT, is a brake on a zip line that acts without participant input when the primary brake fails to prevent catastrophic injury or death. Other emergency braking systems may exist that are not covered in this white paper, however all EADs must meet ACCT and ASTM criteria.

As previously stated, the discrepancies between right and wrong EADs can mean the difference between life and death for a participant. Zip line installers, designers, and engineers must ensure that adequate EADs are included in their installations. EADs that are properly designed and installed considerably lower the risk of participant injury or death, which benefits not only the specific installation but the entire industry. Meeting or exceeding industry standards will greatly lessen the risk associated with this fascinating activity and increase industry confidence.

Planning a zipline installation? Need expert advice on zipline design?

Get started Today

Zipwire braking systems

We offer a full family of zip line brakes that increase throughput with a hands-free braking experience for zip line riders and operators, and a full ecosystem of zip line products to outfit the best zip line builds in the world.

We utilize our patented eddy current magnetic braking technology to create a comfortable braking experience. Magnetic eddy current braking is extremely reliable and low maintenance due to no contacting parts in the braking system.

Beyond the Basics: Unveiling Zipline Technology with Expert Analysis

Intrigued by the potential of Zipline technology? You’ve come to the right place! This article provides a solid foundation. But if you’re eager to delve deeper and gain insights from industry experts, keep reading…

- Two-Way Adventure: Bi-Directional Zipline Trolley Solutions

- Considering operating and investing in a zipline?

- 9 Zipline Mistakes You Don’t Know You’re Making

- Magnetic Zipline Braking: A Revolutionary Way to Ensure Safe Rides

- Pros and Cons of Different Zip Line Brakes

- Maximizing Zip Wire Park Revenue with a Speed-regulating zipline trolley

- White Paper on Zipline Emergency Arrest Devices (EAD)

- The Importance of Optimizing Zip Line Design for Rider Speed

- Does your zip line need an emergency arrest device?

- The Magnetic Self-braking Zipline pulley

- Zipline Braking and landing considerations

- Why Zip Line Trolley Bearings Matter

- Whitepaper: Zipline Braking Dynamics

- Zip Line Installation: Give them the Best Ride

- How to startup a Successful Zip Line Business

-

Zipline Spring Brake System | Primary & EAD Braking€ 80,00 Ex VAT

Zipline Spring Brake System | Primary & EAD Braking€ 80,00 Ex VAT -

Product on sale

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT

zipSTOP IR Zip Line Brake | Internal Reduction for High-Speed ArrivalPrice range: € 5.742,00 through € 5.894,00 Ex VAT -

Product on sale

zipSTOP SPEED | High-Velocity Magnetic Braking SystemPrice range: € 6.198,00 through € 6.455,00 Ex VAT

zipSTOP SPEED | High-Velocity Magnetic Braking SystemPrice range: € 6.198,00 through € 6.455,00 Ex VAT